What Are PVC Ceiling and Wall Panels?

PVC ceiling and wall panels are an innovative and practical solution used to enhance both residential and commercial interiors. PVC stands for Polyvinyl Chloride, a type of plastic that is widely used in a variety of construction materials due to its versatility, durability, and affordability. These panels are primarily made from PVC but can be combined with other materials like calcium carbonate, fiberglass, or polymer additives to enhance specific properties such as strength, flexibility, and resistance to moisture.

Composition and Features:

- Core Material – PVC:

- The primary material in these panels is PVC (Polyvinyl Chloride), a lightweight yet sturdy plastic. The inherent properties of PVC make the panels resistant to moisture, humidity, chemicals, and corrosion, making them ideal for areas prone to water exposure, like bathrooms and kitchens.

- PVC panels can also come with a hollow core design, which further contributes to their lightweight nature and makes them easier to handle during installation.

- Additional Materials:

- Calcium Carbonate: Some PVC panels include calcium carbonate to enhance their rigidity and strength, making them more impact-resistant.

- Fiberglass: Certain panels may incorporate fiberglass or polymer blends to provide additional reinforcement and insulation.

- UV Coating: Many high-quality PVC panels have a UV-resistant coating, helping to protect the panels from fading or discoloration due to sunlight exposure, especially in rooms with a lot of natural light.

How PVC Ceiling Panels Are Produced?

PVC ceiling panels are manufactured through a process that combines polyvinyl chloride (PVC) with other materials to create a lightweight, durable, and versatile product. Below is an overview of the general steps involved in the production of PVC ceiling panels:

1. Material Preparation

The production of PVC ceiling panels begins with the preparation of raw materials:

- PVC Resin: The primary component of the panels is PVC resin, which is mixed with other additives such as plasticizers, stabilizers, fillers, pigments, and flame retardants. These additives are crucial in giving the final product its flexibility, color, and resistance properties.

- Additives: Depending on the desired properties of the ceiling panels (e.g., fire resistance, UV stability, or antibacterial properties), different chemicals and additives are blended with the PVC resin. For example:

- Plasticizers are used to make the panels flexible.

- Stabilizers help prevent degradation from heat and UV light.

- Pigments give the panels their color and design.

2. Mixing and Extrusion

Once the raw materials are prepared, they are mixed and then processed using an extrusion machine:

- Extrusion: The PVC mixture is heated until it melts into a viscous liquid, which is then forced through an extrusion die to form the flat panel shape. The extrusion die is designed to produce the specific dimensions of the ceiling panels, such as width and thickness.

- Shape Formation: The molten PVC flows through the die and is shaped into a continuous flat panel. The panel may have different surface textures, such as smooth, embossed, or textured finishes, depending on the type of mold used.

- Cooling: The extruded PVC panels are cooled down by water cooling systems or air cooling tunnels, solidifying them into the desired form. During this process, the panels maintain their shape and smooth surface.

3. Cutting to Size

After cooling, the long, continuous panels are cut into specific lengths according to customer or project requirements. This can be done using automated cutting machines.

- Custom Lengths: The panels are typically cut to standard lengths (e.g., 8 feet, 10 feet, or custom lengths as needed).

- Edges: The edges of the panels are often smooth or tongue-and-groove to allow easy installation and ensure a tight fit during assembly.

4. Surface Treatment

To enhance the visual appeal and durability of the PVC panels, they may undergo various surface treatments:

- Embossing or Texturing: To mimic the appearance of materials like wood, stone, or marble, the surface of the panels is embossed using rollers with specific patterns. This gives the panels a more realistic look while maintaining the durability and ease of maintenance of PVC.

- Coating: Some PVC ceiling panels are coated with a UV-resistant layer to prevent color fading over time. This coating also helps protect the panels from yellowing or degradation caused by exposure to sunlight.

- Printing: Digital or screen printing can be used to apply intricate designs or patterns to the surface of the panels, offering additional customization options.

5. Quality Control

Before being packaged and shipped, PVC ceiling panels undergo rigorous quality control processes to ensure they meet industry standards:

- Strength Testing: Panels are tested for impact resistance, flexibility, and structural integrity to ensure they meet the required durability standards.

- Surface Inspection: The surface is carefully inspected for defects, such as scratches, uneven patterns, or discoloration.

- Dimensional Checks: The size and thickness of each panel are measured to ensure uniformity and compliance with specifications.

6. Packaging and Shipping

Once the panels pass quality checks, they are packed for shipment. Packaging is done carefully to prevent any damage during transit.

- Protective Packaging: The panels are often wrapped in protective films or shrink-wrapped to safeguard the surfaces.

- Stacking: Panels are stacked neatly and securely in pallets or boxes to prevent damage or warping during transport.

7. Optional Additions

Some PVC ceiling panels may undergo additional processes depending on the desired functionality or design:

- Fire Retardant Treatment: Some panels are treated to be fire-resistant, meeting fire safety standards for use in commercial or high-risk areas.

- Sound Insulation: For specific applications, such as office buildings or multi-story homes, PVC panels may be engineered with additional soundproofing properties.

- Antibacterial Coating: In some cases, antibacterial coatings are applied to the panels, especially for use in kitchens, bathrooms, or hospitals.

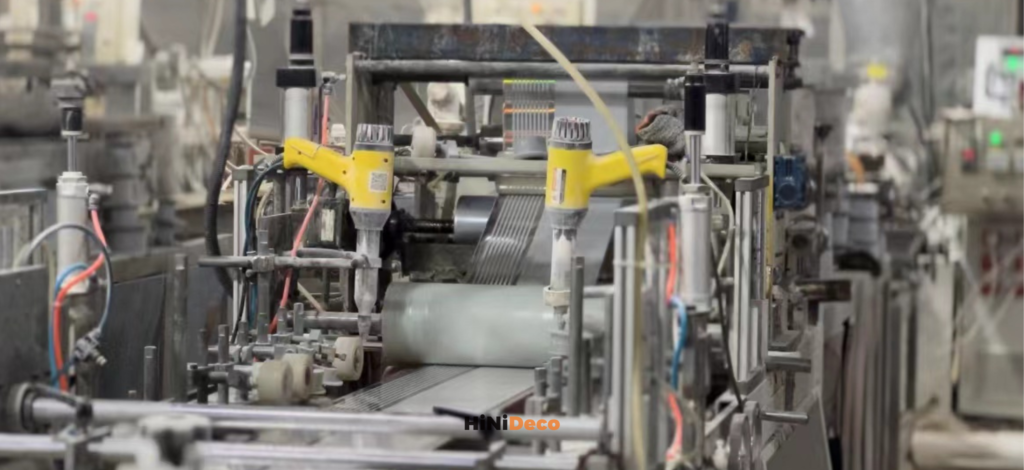

What kind of machine used?

The production of PVC ceiling and wall panels involves several types of machinery, each serving a specific purpose in the manufacturing process. Below are the main machines used in the production of PVC ceiling panels:

1. Extruder Machine

The extruder machine is the core piece of equipment used to melt and shape the PVC material. It is responsible for transforming raw PVC resin and additives into the final panel form.

- Function: The PVC resin and additives are fed into a screw extruder, where they are heated and melted to form a viscous material. This melted material is then pushed through a molding die to form a continuous sheet or panel.

- Components: The extruder machine consists of a feeding hopper, heating system, screw conveyor, and mold/die.

- Types: There are various types of extruders used, such as single screw extruders and twin screw extruders. Twin screw extruders are more commonly used for PVC panels because they allow better mixing of materials, ensuring uniform consistency.

2. Cooling System

Once the PVC material exits the extruder die, it needs to cool down and solidify into its final shape.

- Function: The cooling system typically involves water cooling tanks or air cooling tunnels.

- Water Cooling: In the water cooling system, the freshly extruded PVC panels pass through a tank of cool water, which helps solidify the material and set its shape.

- Air Cooling: Some systems use large fans or air cooling tunnels to rapidly cool down the panels after extrusion.

3. Embossing Machine (Optional)

For PVC ceiling and wall panels that require a textured or embossed surface (e.g., to resemble wood grain, marble, or stone), an embossing machine is used.

- Function: The embossing machine applies a pattern or texture to the surface of the PVC panel. This is done by pressing the PVC material between two rollers or plates, each with a specific pattern.

- Types: There are various patterns that can be created, such as wood texture, stone finish, marble patterns, or smooth finishes.

4. Printing Machine

If the panels require printed designs, patterns, or graphics (for example, marble or wood patterns), a printing machine is used.

- Function: Digital or screen printing methods are employed to apply designs directly onto the surface of the panels. This allows for custom designs and patterns that enhance the aesthetics of the panels.

- Types: There are UV printers or screen printing machines that print directly on the PVC surface, ensuring vibrant, long-lasting colors.

5. Cutting Machine

After extrusion and cooling, the continuous sheets of PVC are cut into panels of the required lengths.

- Function: The cutting machine cuts the extruded PVC sheet into custom lengths. The machine ensures precision, allowing the panels to be cut to standard sizes (e.g., 8 feet, 10 feet, or customized lengths).

- Types: Rotary cutting machines or guillotine cutters are commonly used. These machines are equipped with sharp blades or saw mechanisms that ensure clean cuts without damaging the panels.

6. Edge Processing Machine

This machine is used to treat the edges of the PVC panels, particularly if they are tongue-and-groove or require a specific edge profile.

- Function: The edge processing machine smoothens or shapes the edges of the panels for better fit during installation. It can also apply grooves or tongues that help interlock panels during the assembly process.

- Types: Trimming machines, grooving machines, and profiling machines are used to create the necessary edge features.

7. Cutting and Trimming Machine (Optional)

For panels with custom sizes, this machine trims the edges to meet specific dimensional requirements or to create special finishes.

- Function: It trims any excess material or adjusts the edges to a perfect finish. It ensures that each panel has a uniform, smooth edge and is ready for packaging.

- Types: Band saws, rotary knives, or circular saws are used to cut the PVC panels with precision.

8. Quality Control Machines

Various quality control machines are used to ensure that the final product meets industry standards.

- Thickness Measuring Machines: These machines measure the thickness of the panels to ensure uniformity.

- Impact and Hardness Testing Machines: These machines test the durability and strength of the panels by subjecting them to different stress levels.

- Surface Inspection Machines: These machines inspect the panels for any surface defects, such as scratches, bubbles, or imperfections.

9. Packaging and Palletizing Machine

After production, PVC panels need to be packaged and prepared for shipment.

- Function: Packaging machines wrap the finished panels in protective film or shrink wrap to protect them from scratches and damage during transport.

- Palletizing: Panels are stacked on pallets by automated machines and secured for shipment.

Versatility of PVC Ceiling and Wall Panels

One of the key advantages of PVC ceiling and wall panels is their incredible versatility. These panels are designed to be used in a variety of applications, making them an excellent choice for both residential and commercial spaces. Their ability to perform across different environments, coupled with a wide range of design options, allows them to cater to diverse aesthetic preferences and functional needs.

Multi-Functional Use:

- Ceilings:

- PVC panels are often used as ceiling coverings because they provide an attractive, seamless look and are easy to install. Whether you’re looking to enhance a living room, bathroom, or kitchen ceiling, these panels offer a stylish, modern finish that is both durable and moisture-resistant.

- Waterproof properties make PVC ceiling panels particularly ideal for kitchen ceilings, where humidity, cooking vapors, and grease can be a concern. They’re also a great solution for bathroom ceilings, preventing mold and mildew growth.

- Walls:

- PVC wall panels offer a quick and cost-effective solution for covering walls in living rooms, bedrooms, hallways, or commercial spaces like offices, restaurants, and hotels. These panels not only serve as functional wall coverings but also contribute to the aesthetic appeal of the room.

- PVC panels are highly moisture-resistant, making them perfect for bathroom walls, kitchen backsplashes, and wet rooms, where traditional wall materials like drywall or plaster may degrade over time.

Applications in Various Spaces:

- Kitchens: PVC panels are a go-to choice for both walls and ceilings in kitchens. They are resistant to moisture, heat, and stains, making them ideal for spaces where splashes and spills are common. With various textures like marble, wood grain, or glossy finishes, they can complement any kitchen style.

- Bathrooms: Since PVC is waterproof and resists mold and mildew, it’s an ideal material for both bathroom walls and ceiling coverings. Whether it’s for residential bathrooms or public restroom facilities, PVC panels maintain their integrity in damp conditions while offering easy-to-clean surfaces.

- Living Rooms and Bedrooms: In living rooms and bedrooms, PVC panels can be used on both walls and ceilings to create a stylish, modern interior. Whether you’re looking to add a minimalist touch or something more luxurious, PVC panels are available in various textures, colors, and finishes, from sleek high-gloss looks to natural wood-like finishes.

- Offices and Commercial Spaces: For offices, hotels, restaurants, and other commercial spaces, PVC panels are a cost-effective solution for creating polished walls and ceilings that can withstand high traffic, moisture, and occasional wear. They’re also easy to maintain, which is a big advantage in spaces with busy environments.

- Basements and Hallways: Because of their durability and moisture resistance, PVC panels are also perfect for basements and hallways. These spaces are often prone to humidity and need materials that can stand up to these conditions while maintaining a fresh, modern look.

Key Features and Benefits of PVC Ceiling and Wall Panels?

1. Durability

PVC ceiling and wall panels are known for their long-lasting qualities, making them a smart investment for both residential and commercial properties. These panels are highly resistant to common issues that affect traditional building materials, such as moisture, humidity, and wear. This resistance makes them ideal for use in high-moisture environments such as bathrooms, kitchens, and basements, where other materials might warp, deteriorate, or grow mold over time.

- Impact Resistance: PVC panels are impact-resistant, meaning they can withstand accidental bumps or knocks without damage, maintaining their appearance for years.

- Long-Lasting Finish: The durability of PVC panels ensures that they retain their color and texture even in harsh conditions.

2. Lightweight

One of the standout features of PVC panels is their lightweight nature, which makes them easier to handle, transport, and install. This benefit has several practical advantages:

- Easier Handling: Since PVC panels are light, installers don’t need to worry about cumbersome, heavy materials, which reduces labor strain and increases installation speed.

- Lower Shipping Costs: The light weight of PVC panels also translates into lower shipping costs, making them more affordable to transport, especially when purchasing in bulk.

- DIY-Friendly: For homeowners or small-scale renovators, the lightweight nature of PVC panels makes them ideal for DIY installation. Even those with minimal experience can install these panels easily, reducing the need for professional installers.

3. Easy to Maintain

Unlike traditional ceiling and wall materials like drywall, plaster, or wood, PVC panels require minimal upkeep. Their easy maintenance is one of the main reasons they are preferred in areas subject to high wear and tear.

- Resistant to Mold and Mildew: PVC panels are naturally resistant to mold and mildew, which is essential for keeping walls and ceilings in high-humidity environments like bathrooms and kitchens clean and healthy.

- Stain Resistance: PVC panels are also stain-resistant. Spills, dirt, and grease can be wiped away easily without leaving permanent marks, making these panels perfect for kitchens and high-traffic areas.

- Low Maintenance: Regular cleaning is simple—just wipe them down with a damp cloth and mild detergent to keep them looking brand new without the need for special cleaning products or treatments.

4. Waterproof

The waterproof nature of PVC panels makes them a standout choice for spaces prone to water damage, such as bathrooms, kitchens, laundries, and basements. Unlike traditional materials like drywall or wood, PVC panels do not absorb moisture, preventing issues like swelling, warping, or decay.

- Moisture Resistance: PVC panels prevent water from seeping into walls or ceilings, making them an excellent choice for areas with frequent exposure to water, such as around showers, bathtubs, sinks, and kitchen counters.

- Prevent Mold Growth: Since PVC panels don’t trap moisture, they significantly reduce the risk of mold and mildew growth, maintaining a healthier indoor environment.

5. Aesthetic Appeal

PVC panels are not only practical but also aesthetically versatile, offering a wide range of designs, textures, and finishes. Whether you’re aiming for a modern, traditional, or contemporary look, these panels can fit into any design scheme.

- Variety of Finishes: PVC ceiling and wall panels come in numerous finishes, such as wood grain, marble, glossy, and matte surfaces. These finishes allow you to create the perfect ambiance in any room.

- Customization Options: For clients looking for a unique or tailored solution, many manufacturers, including HiNiDeco, offer custom designs that match specific colors or textures.

- Modern Look: With their sleek and stylish appearance, PVC panels help create a clean, modern look. Their smooth, polished finish makes them ideal for contemporary interiors, giving spaces a fresh, sophisticated vibe.

Summary of Benefits:

- Durability: Resistant to moisture, humidity, and wear, perfect for high-moisture areas like bathrooms and kitchens.

- Lightweight: Easy to handle, install, and ship, making them ideal for both professionals and DIY enthusiasts.

- Easy Maintenance: Low-maintenance material that resists mold, mildew, and stains, and only requires occasional wiping to keep clean.

- Waterproof: Offers complete moisture protection, making them a reliable option for wet environments.

- Aesthetic Appeal: Available in a variety of finishes and custom designs to suit various interior styles, from wood-look finishes to glossy and matte surfaces.

PVC ceiling and wall panels combine practicality and style, making them the perfect choice for those seeking durability, low maintenance, and aesthetic flexibility, all at an affordable price. Whether for residential or commercial use, they offer a smart, long-lasting solution for modern interiors.

Design Versatility of PVC Ceiling and Wall Panels

One of the standout advantages of PVC ceiling and wall panels is their exceptional design versatility. With an extensive range of styles, textures, and finishes, these panels offer unmatched aesthetic flexibility, allowing homeowners, interior designers, and commercial space planners to create the perfect look for any environment, whether contemporary, traditional, or somewhere in between.

Aesthetic Flexibility

PVC panels are available in a wide variety of finishes, making them a versatile choice for any design scheme. The panels can mimic the appearance of wood, stone, metal, marble, and more, giving you the flexibility to achieve the look of high-end materials without the high cost or maintenance.

- Wood-Look Panels: PVC panels that imitate natural wood provide a warm, organic feel while being much easier to maintain. Whether it’s a light oak, deep walnut, or rustic reclaimed wood look, these panels give you the charm of wood without the risk of warping or damage from moisture.

- Stone and Marble Effects: For a luxurious and sophisticated appearance, PVC panels with stone or marble effects can bring the elegance of these materials to walls and ceilings. These panels give you the high-end look of natural stone without the hefty price tag and maintenance requirements.

- Metallic Finishes: Metallic-look PVC panels offer a sleek and modern aesthetic, perfect for industrial or contemporary designs. Whether you’re going for a brushed steel, copper, or bronze effect, these panels add a touch of glamour and sophistication.

- Glossy and Matte Surfaces: Depending on your desired effect, PVC panels come in both glossy and matte finishes, catering to both shiny, modern aesthetics and more subtle, understated designs.

Customization

At HiNiDeco, we understand that every space has its own unique needs and vision. That’s why we offer custom-designed PVC panels tailored to meet the specific requirements of each client. Whether you’re looking for custom colors, finishes, or even panel dimensions, we ensure that our panels align perfectly with your interior design vision.

- Tailored Colors: If you have a particular color palette for your space, we can provide PVC panels in custom shades that match your décor or branding, allowing for a seamless integration of the panels into the overall theme.

- Unique Finishes: For clients with specific design goals, HiNiDeco provides options to create custom textures and finishes, such as exclusive wood grains, specialty metallic effects, or even bespoke stone patterns.

- Panel Dimensions: In addition to offering various standard sizes, HiNiDeco can provide custom panel dimensions, ensuring that the panels fit perfectly within the architecture of your space. This flexibility makes PVC panels ideal for both small residential projects and large-scale commercial installations.

Trendy Designs

PVC ceiling and wall panels are not just practical—they are also highly adaptable to the latest interior design trends. Whether you are designing for a modern home, a luxurious hotel, or a stylish office, PVC panels can help you create the perfect atmosphere to complement current design movements.

- Minimalism: In minimalist interiors, PVC panels can offer a sleek, clean, and uncluttered aesthetic. The smooth finish of PVC panels can easily align with the principles of minimalist design, creating a calm and serene environment. Neutral colors, matte finishes, and subtle textures are perfect for achieving the understated elegance that is characteristic of minimalist spaces.

- Industrial Style: For spaces inspired by the industrial aesthetic, PVC panels with metallic or cement-like finishes can evoke the look of raw, unfinished materials while still offering durability, ease of maintenance, and a modern twist. The rugged charm of industrial designs can be created by using PVC panels with exposed brick or concrete effects.

- Luxury Aesthetics: PVC panels with marble, stone, or high-gloss finishes are a natural fit for luxury interiors. These panels add a touch of elegance and sophistication to high-end residential homes, hotel lobbies, premium offices, and boutique spaces. The flexibility of PVC allows designers to introduce luxurious materials without the high maintenance or installation costs.

Summary of Design Versatility:

- Aesthetic Flexibility: PVC panels come in a vast array of designs, including wood, stone, marble, metallic, and custom options, ensuring that there’s a look to suit any style.

- Customization: HiNiDeco offers custom-designed panels, from color and texture to dimensions, enabling complete alignment with your unique design vision.

- Trendy Designs: PVC panels are versatile enough to complement modern design trends such as minimalism, industrial, and luxury aesthetics, making them an ideal choice for contemporary spaces.

Cost-Effectiveness of PVC Ceiling and Wall Panels

PVC ceiling and wall panels offer a cost-effective solution for both residential and commercial projects. When compared to traditional building materials like drywall, plaster, or wood, PVC panels deliver exceptional value without compromising on aesthetic appeal or durability. Whether you’re working with a tight budget or undertaking a luxury renovation, PVC panels are a smart and affordable choice.

Affordable Solution

PVC panels are often significantly more affordable than traditional building materials such as drywall, plaster, and wood, making them an excellent choice for those looking to maximize their budget.

- Lower Material Costs: PVC is a cost-effective material that requires fewer resources to produce, and it offers a higher yield per square meter compared to natural materials like wood or stone, which can drive up the overall material costs.

- Labor Savings: PVC panels are easy to handle and quick to install, which reduces labor costs. Professional installers can complete the project in less time, while DIY enthusiasts can tackle installation without specialized skills or tools, further lowering installation costs.

- No Need for Additional Treatments: Unlike wood or plaster, PVC panels don’t require painting, sealing, or finishing, which reduces both upfront and ongoing costs.

Long-Term Investment

While PVC panels are affordable upfront, their real cost benefits become clear over time. Their durability and low-maintenance nature make them a long-term investment that offers significant savings in repair and replacement costs.

- Resistant to Damage: PVC panels are highly durable and resistant to common issues like moisture damage, mold growth, and wear and tear. This durability ensures that the panels remain in great condition for many years, even in high-traffic or high-moisture environments like bathrooms, kitchens, or offices.

- Minimal Maintenance Costs: Unlike other materials that require frequent maintenance (e.g., repainting, sealing, or refinishing), PVC panels are easy to clean and don’t require constant upkeep. This reduces the need for maintenance crews or repair work, translating into lower overall lifetime costs.

- Long-Lasting Aesthetic Appeal: PVC panels retain their appearance for many years without fading, cracking, or deteriorating. This means that you don’t need to worry about costly replacements or repairs down the line, which is common with other materials like wood or plaster that can be damaged by moisture or wear.

Competitive Pricing

At HiNiDeco, we offer high-quality PVC panels at affordable rates, ensuring that our customers get the best value for their investment. Our pricing is competitive compared to traditional building materials, allowing you to achieve your design vision without exceeding your budget.

Sustainability and Eco-Friendliness of PVC Ceiling and Wall Panels

As the demand for environmentally friendly building materials grows, PVC ceiling and wall panels have emerged as an excellent choice for sustainable design. These panels are not only cost-effective and aesthetically versatile but also eco-friendly, making them the ideal option for environmentally conscious consumers and businesses. Below are key points highlighting the sustainability and eco-friendliness of PVC panels.

Recyclable Material

One of the most significant environmental benefits of PVC panels is that they are made from recyclable materials. Unlike traditional materials such as wood or plaster, PVC panels can be repurposed and recycled at the end of their life cycle, reducing waste in landfills and minimizing environmental impact.

- Closed-Loop Recycling: PVC panels can be recycled and used to create new products, ensuring that valuable resources are reused instead of discarded. This closed-loop recycling process helps conserve natural resources and reduces the need for virgin materials.

- Reduced Environmental Footprint: By opting for PVC panels, you are supporting a circular economy, where the materials used to create the panels are reused and repurposed rather than being discarded. This results in a lower carbon footprint and reduced strain on landfills.

Energy Efficiency

PVC panels also contribute to energy-efficient building designs. Their insulating properties help create more comfortable indoor environments while reducing the need for constant heating or cooling, which can lead to energy savings over time.

- Thermal Insulation: PVC panels provide a degree of thermal insulation, which helps keep interiors cooler in the summer and warmer in the winter. This reduces the reliance on air conditioning and heating systems, ultimately leading to lower energy consumption and reduced energy costs.

- Reduced Carbon Emissions: By helping to lower energy consumption, PVC panels indirectly contribute to reducing carbon emissions associated with the use of electricity or heating fuels. This makes them a key component of green building designs aimed at improving energy efficiency.

Low Emissions and Indoor Air Quality

Many PVC panels are now produced with low-VOC (volatile organic compound) materials, making them a healthier choice for both indoor air quality and the environment.

- Low-VOC Panels: High-VOC products release harmful chemicals into the air, which can contribute to indoor air pollution and negatively affect the health of building occupants. Low-VOC PVC panels, on the other hand, help maintain better indoor air quality, making them ideal for homes, offices, schools, and hospitals.

- Healthier Environment: By choosing low-VOC PVC panels, consumers can help ensure that the air within their living or working spaces remains clean and safe. This is especially important in environments where sensitive individuals, such as children, the elderly, or people with respiratory conditions, spend a lot of time.

Installation Process of PVC Ceiling and Wall Panels

One of the key benefits of PVC ceiling and wall panels is their easy installation process. Whether you’re a DIY enthusiast or need professional help for larger projects, PVC panels offer a flexible and efficient solution for a wide range of applications. Here’s an overview of the installation process, covering both DIY and professional installation options.

DIY-Friendly Installation

PVC panels are particularly DIY-friendly, making them an ideal choice for homeowners or small project managers looking to renovate or upgrade their spaces without hiring professional contractors. Installing PVC panels is quick and straightforward, even for those with minimal experience in home improvement.

- Simple Steps: PVC panels are designed to be easy to handle and install. They typically come with a tongue-and-groove system, which allows the panels to snap together seamlessly, ensuring a secure fit with minimal effort.

- Time-Saving: The installation process is fast, meaning homeowners can transform their spaces without needing to wait days for installation to be completed. This is especially beneficial for bathroom remodels, kitchen upgrades, or any quick turnaround projects.

- Clean Installation: Since PVC panels are lightweight, they are easy to cut and handle. This reduces the risk of mess and the need for additional cleanup once the project is complete.

Professional Installation

For larger or more complex projects, or for spaces where precision and expertise are essential (e.g., commercial environments, large bathrooms, or intricate designs), professional installation services are also available.

- Expert Assistance: Professional installers are well-equipped to handle any complications that may arise during the installation process. They have the knowledge and tools necessary to ensure that the PVC panels are installed correctly, securely, and with the utmost attention to detail.

- Secure and Long-Lasting: Professionals can ensure that the panels are properly aligned, securely fixed, and aesthetically pleasing, avoiding common installation mistakes that might occur with DIY methods.

- Efficiency: Professionals can complete larger installations much more quickly than most DIYers, which can be especially beneficial for commercial spaces that need to minimize downtime or disruption.

Minimal Tools Needed

One of the reasons PVC panels are so popular for both DIY and professional projects is that the installation process requires very few tools, making it accessible and budget-friendly.

- Basic Tools: To install PVC panels, you only need a few basic tools:

- Adhesive: A strong, non-toxic adhesive is typically used to secure the panels to the surface. A PVC-compatible adhesive is ideal for ensuring a long-lasting bond.

- Cutting Tools: Depending on the panel size, you may need to cut some panels to fit the dimensions of your space. A fine-toothed saw, utility knife, or circular saw can be used to trim PVC panels to size.

- Clamps: Clamps can help hold the panels in place while the adhesive sets, ensuring a secure fit during installation.

- Measuring Tape and Level: Proper measurements are key to ensuring the panels are installed straight and evenly. A measuring tape and level help maintain alignment during the process.

- Easy to Cut: PVC panels are relatively soft and easy to cut, requiring less effort compared to harder materials like wood or ceramic tiles. This allows for precise measurements and a clean installation without the need for advanced tools or skills.

Durability and Performance of PVC Ceiling and Wall Panels

When it comes to ceiling and wall solutions, durability and performance are key factors that determine the longevity and effectiveness of the materials used. PVC ceiling and wall panels excel in these areas, offering outstanding resilience and performance over time. Below are some of the key features that contribute to their exceptional durability.

Long Lifespan

One of the major advantages of PVC panels is their long lifespan. Unlike traditional materials like wood, plaster, or drywall, PVC panels are resistant to a variety of issues that can degrade other materials over time.

- No Warping or Cracking: PVC panels won’t warp, crack, or peel, even in challenging environments like humid bathrooms or moist kitchens. This ensures that the panels maintain their appearance and functionality over many years.

- Low Maintenance: Due to their durability, PVC panels require minimal upkeep. They don’t need to be painted, sealed, or refinished regularly, which helps keep long-term costs low.

- Weather Resistance: PVC panels are resistant to moisture and humidity, making them ideal for high-moisture areas. They don’t absorb water, so they won’t swell or degrade like wood or drywall.

Impact Resistance

Another significant advantage of PVC panels is their impact resistance. These panels are highly durable and able to withstand the bumps and impacts commonly found in high-traffic areas.

- High Traffic Areas: Whether in commercial spaces, busy kitchens, or hallways, PVC panels are designed to absorb and withstand physical impacts without cracking or denting. This makes them a great option for spaces that experience a lot of wear and tear.

- Kid and Pet-Friendly: PVC panels are resilient enough to withstand impacts from children’s toys, pets, or even accidental bumps, keeping the surfaces intact and looking pristine.

Fire Retardant Properties

Some PVC panels come with fire-resistant properties, providing an added layer of safety in both residential and commercial settings.

- Fire Safety Standards: Fire-retardant PVC panels meet industry safety standards, making them a reliable choice for applications where fire safety is a concern. This is particularly important in commercial spaces, public buildings, or high-rise apartments where safety regulations are more stringent.

- Peace of Mind: For homeowners and businesses looking to improve fire safety, fire-resistant PVC panels offer an extra level of security, reducing the risk of fire spreading through the ceiling or walls.

Noise Reduction

Some PVC panels also provide sound insulation benefits, which can enhance the comfort and functionality of living and working spaces.

- Sound Absorption: Certain types of PVC panels come with built-in acoustic properties, helping to reduce noise transmission between rooms or floors. This is especially beneficial in multi-story buildings, offices, or apartments, where noise can be a concern.

- Quieter Environments: By absorbing sound waves, PVC panels help create quieter spaces, reducing unwanted noise and improving the overall acoustics of the room.

Customer Testimonials and Case Studies for HiNiDeco PVC Ceiling and Wall Panels

At HiNiDeco, we are proud of the positive impact our PVC ceiling and wall panels have had on our customers’ projects. From residential remodels to commercial installations, our panels have helped elevate spaces with their exceptional durability, aesthetic appeal, and ease of installation. Here are some real-life client success stories and positive reviews that demonstrate the quality and benefits of choosing HiNiDeco products.

Client Success Stories

Project 1: Modern Bathroom Renovation

- Client: Homeowner (Residential)

- Location: sofia, Bulgaria

- Project Scope: Complete renovation of a bathroom with a focus on water resistance and modern aesthetics.

Challenge: The client wanted to upgrade their outdated bathroom with a modern, waterproof solution that would be both durable and easy to maintain.

Solution: HiNiDeco’s PVC wall panels were chosen for their water-resistant properties and stylish marble effect finish. The panels were installed on both the walls and ceiling to give the bathroom a sleek, polished look.

Results:

- Aesthetic Appeal: The panels’ high-gloss finish and modern design transformed the bathroom into a contemporary oasis.

- Easy Maintenance: The homeowner reported that cleaning the panels was incredibly easy and that the bathroom had no issues with moisture buildup or mold.

- Time-Saving: The installation process was quick, reducing renovation downtime and allowing the client to enjoy their new bathroom much sooner.

Customer Feedback:

“I couldn’t be happier with the result! The PVC panels not only look fantastic but are so easy to clean. I love that I don’t have to worry about mold or peeling anymore.”

Project 2: Office Space Transformation

- Client: Commercial Interior Design Firm

- Location: THESSALONIKH, Greece

- Project Scope: Office space renovation with a focus on creating a modern, professional atmosphere while reducing noise transmission.

Challenge: The office was located in a busy commercial building, and noise reduction was a key priority. The design firm needed a durable, easy-to-install solution that would also complement their minimalist design vision.

Solution: HiNiDeco’s PVC ceiling panels with sound insulation properties were installed across the ceiling and walls. The panels were chosen for their clean design, ease of installation, and acoustic benefits.

Results:

- Noise Reduction: Employees reported a noticeable improvement in sound quality, with less noise disturbance from the surrounding offices and the street.

- Quick Installation: The easy-to-install panels minimized disruption to office operations, allowing the business to resume normal functions without extended downtime.

- Cost-Effective Solution: The firm saved on both labor and material costs compared to traditional drywall and acoustic tiles.

Customer Feedback:

“The PVC panels were a game-changer. They gave us the sleek, professional look we wanted, and the added benefit of noise reduction has made a big difference in our office environment. Installation was fast and hassle-free!”

Project 3: Restaurant Makeover

- Client: Restaurant Owner (Commercial)

- Location: Lagos, Nigeria

- Project Scope: A full restaurant renovation aimed at creating a fresh, modern ambiance while ensuring the space was easy to maintain and resistant to cooking fumes and humidity.

Challenge: The client needed a material that would stand up to the demanding conditions of a commercial kitchen and dining area. The material also needed to be easy to clean and maintain.

Solution: HiNiDeco’s PVC wall and ceiling panels were chosen for their moisture resistance, durability, and cleanability. The panels were installed throughout the dining area and kitchen, featuring a stylish wood-grain finish to enhance the restaurant’s rustic-modern aesthetic.

Results:

- Durability and Resistance: The panels proved resistant to the high levels of steam, smoke, and oil common in restaurant kitchens.

- Aesthetic Transformation: The panels brought a contemporary, welcoming vibe to the dining area, greatly enhancing the overall customer experience.

- Low Maintenance: The restaurant owner mentioned that the ease of cleaning the panels was a huge benefit, as it reduced downtime for maintenance.

Customer Feedback:

“The PVC panels have truly transformed our space. Not only do they look amazing, but they are incredibly durable in the high-moisture environment of a restaurant. Cleaning is a breeze, and we’ve noticed a significant improvement in the overall atmosphere of the restaurant.”

Explore the Range

Discover HiNiDeco’s exclusive collection of high-quality PVC ceiling and wall panels. From contemporary designs to timeless classics, find the perfect match for your space. Browse the Catalog Now!

Contact for Customization

Need something unique? HiNiDeco offers personalized design solutions tailored to your specific project needs. Contact us today for custom orders and designs that reflect your style.

Request Samples

Want to feel the quality before committing? Request a sample or a quote to get a hands-on experience of HiNiDeco’s premium panels. We’re happy to help with any inquiries!

Get in Touch

We’re here for you! Reach out to us via:

- Email: info@hinideco.com

- WhatsApp: +8619817052520

We look forward to assisting you with your next project.

Feel free to adjust the contact details or catalog link to your specific needs!