What is decorative PVC Marble Sheet?

Decorative PVC marble sheet is a type of polyvinyl chloride (PVC) panel that is designed to replicate the look of real marble. It combines the aesthetic appeal of marble with the benefits of PVC, offering a durable, lightweight, and cost-effective alternative to traditional marble. These sheets are used primarily in interior design, providing a luxurious and elegant finish without the high cost or heavy weight of natural marble.

Key Characteristics of Decorative PVC Marble Sheets:

- Appearance:

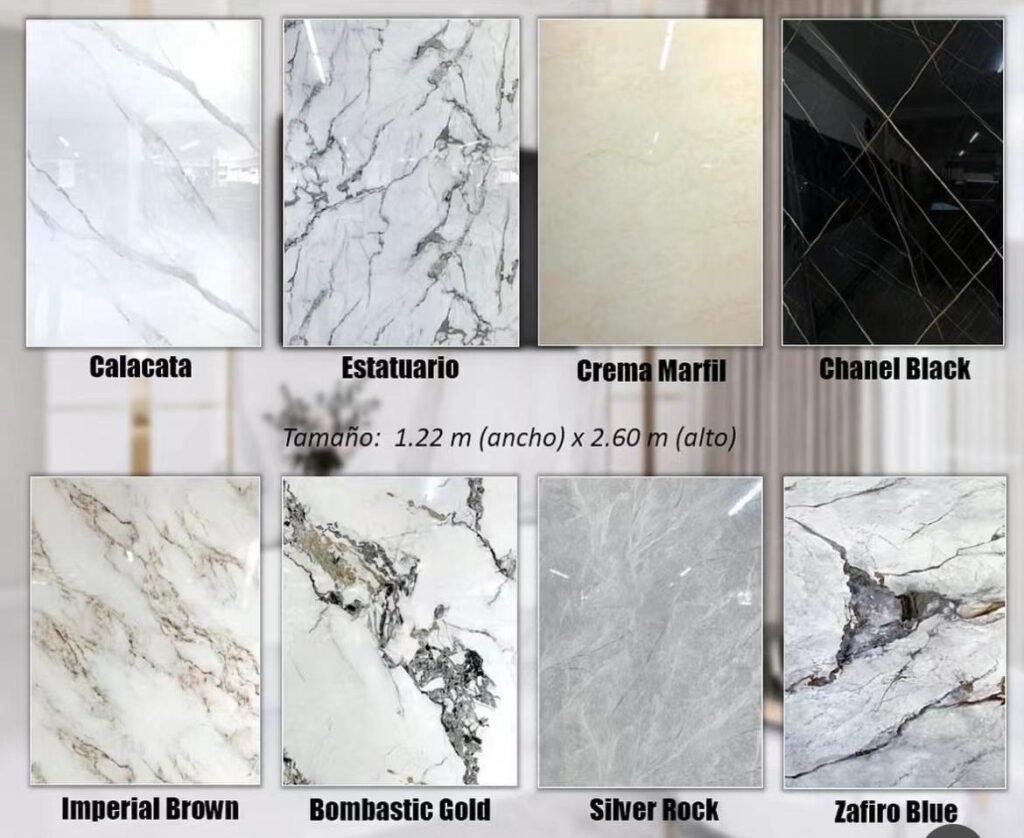

- PVC marble sheets are designed to mimic the appearance of natural marble. They come in a variety of patterns, including the classic white marble with gray veins, black marble, beige, or even more exotic styles with metallic or colorful veining.

- The finish can be glossy, matte, or even 3D-textured, providing a realistic marble effect.

- Material:

- Made from PVC, which is a type of plastic, these sheets are lightweight yet strong. The outer surface is often laminated or printed with a marble design, while the inner structure is made of durable PVC, which makes it moisture-resistant and easy to clean.

- Durability:

- Impact-resistant and scratch-resistant, PVC marble sheets are more durable than natural marble. They are less likely to crack or chip.

- They are also waterproof, making them ideal for wet areas like bathrooms and kitchens.

- Lightweight:

- PVC is much lighter than natural marble, which makes installation easier and reduces shipping costs. This feature also makes it ideal for use in spaces where weight could be a concern, like walls or ceilings.

- Cost-Effective:

- Compared to real marble, PVC marble sheets are much more affordable. They offer the look of marble without the expensive price tag, making them a popular choice for homeowners and businesses alike.

- UV and Fade-Resistant:

- Many decorative PVC marble sheets come with a UV-resistant coating that prevents them from fading over time due to sunlight exposure. This ensures the design remains vibrant and fresh.

Applications of Decorative PVC Marble Sheets:

- Wall Cladding:

- PVC marble sheets are commonly used as wall cladding in living rooms, kitchens, bathrooms, and even offices. They provide an elegant, polished look to walls and can be used as feature walls or as backsplashes.

- Bathroom Use:

- PVC marble sheets are highly suitable for bathroom applications because of their moisture resistance. They are used for shower walls, vanity backsplashes, and toilet surrounds.

- Furniture Surfaces:

- Decorative PVC marble sheets can be used on furniture surfaces like coffee tables, nightstands, and cabinet fronts to provide a luxurious finish without the weight or cost of real marble.

- Countertops:

- While less common than traditional marble, PVC marble sheets can also be used as a countertop covering in kitchens and bathrooms, offering a sleek look with easy maintenance.

- Ceiling Panels:

- For an upscale touch, PVC marble sheets can be applied to ceilings to create a visually stunning effect, particularly in larger rooms or luxurious spaces.

- Flooring:

- PVC marble sheets can be used as flooring or accent tiles to create a marble-inspired look without the expense of marble tiles.

Advantages of Decorative PVC Marble Sheets:

- Affordable Alternative to Marble:

- PVC marble sheets offer a cost-effective alternative to real marble, making them a popular choice for budget-conscious homeowners and businesses who still want the marble aesthetic.

- Easy to Install:

- Many PVC marble sheets come with peel-and-stick backing or can be installed using adhesive glue, making them easy for DIY installation. This reduces labor costs and installation time.

- Low Maintenance:

- Unlike real marble, which needs sealing and special cleaning care, PVC marble sheets are easy to clean and maintain. They are stain-resistant and mildew-resistant, requiring only regular cleaning with a damp cloth.

- Versatility:

- Decorative PVC marble sheets are highly versatile and can be used in a variety of applications, including wall panels, backsplashes, countertops, and furniture surfaces. They can be used in both residential and commercial settings.

- Lightweight and Easy to Handle:

- Their lightweight nature makes PVC marble sheets much easier to handle and cut to size, which is a huge advantage during installation, especially in DIY projects.

- Environmentally Friendly Options:

- Some manufacturers offer eco-friendly PVC marble sheets, made from recycled materials or designed to be recyclable, making them a sustainable option.

Disadvantages of Decorative PVC Marble Sheets:

- Not as Authentic as Real Marble:

- While the look can be very realistic, it still doesn’t quite match the authentic feel and natural variations of real marble. Some people may prefer the genuine texture and quality of natural stone.

- Durability Concerns in High-Impact Areas:

- While durable, PVC marble sheets are still less resistant to high impacts and extreme heat compared to real marble. They may show signs of damage in high-traffic or extreme-use areas if not cared for properly.

- Susceptibility to Scratches:

- While scratch-resistant, over time, sharp objects or rough use can still leave marks on the surface, especially in areas that receive heavy traffic or rough handling.

- Can’t Handle High Temperatures:

- PVC is a plastic material, and while it is heat-resistant to a certain extent, it can warp or discolor if exposed to extremely high temperatures, unlike marble, which is heat-resistant.

- Chemical Sensitivity:

- Some cleaning products or chemicals may damage the finish of PVC marble sheets, so it’s important to use non-abrasive, mild cleaners to avoid discoloration or surface damage.

How about the PVC marble wall panel cost ?

The cost of PVC marble sheets can vary depending on several factors, including the quality, design, thickness, size, brand, and quantity purchased. Here’s an overview of what you can expect:

General Price Range for PVC Marble Sheets:

- Standard PVC Marble Sheets:

- Per Sheet: Prices typically range from $7.9 to $19.9 per sheet(FOB SHANGHAI,CHINA). This is for a basic, single sheet of PVC marble, generally with dimensions around 1220mm x 2440mm (4’ x 8’), though sizes can vary.

- Cost per Square Meter: You may find prices ranging from $2.9 to $5.9 per square meter, depending on the quality and design.

- Premium PVC Marble Sheets:

- For higher-end designs, thicker sheets (3mm to 5mm), or sheets with UV coating and advanced finish (glossy, matte, etc.), prices can range from $20 to $100 per sheet or more. This could be for designs with high-end finishes, more intricate veining patterns, or those that are resistant to staining and fading.

- Budget Options:

- Basic designs or smaller quantities (e.g., 1-2 sheets) may be priced around $8 to $15 per sheet if you’re looking for cheaper, thinner PVC sheets that are used for smaller or less demanding projects.

Factors Affecting Cost:

- Thickness:

- Thicker Sheets (around 3mm to 5mm) will typically cost more, as they offer better durability and a more authentic feel.

- Thinner Sheets (1mm to 2mm) are lighter and less expensive but might not be as durable or as heavy-duty for certain applications.

- Finish:

- Glossy finish sheets tend to be slightly more expensive compared to matte or satin finish sheets due to the higher manufacturing process for a reflective, high-shine surface.

- UV-resistant sheets (which prevent fading and discoloration from sunlight) are usually priced higher than standard sheets.

- Design Complexity:

- Marble veining patterns and realistic designs will generally cost more than solid colors or simpler patterns.

- Exotic designs with gold or metallic veins could also increase the cost.

- Brand and Quality:

- Well-known brands like HiNiDeco that offer high-quality PVC marble sheets with added features (e.g., UV protection, anti-bacterial coatings) will usually command a premium price.

- Budget brands with simpler designs or lower-quality materials will be priced more affordably.

- Quantity:

- Buying in bulk (e.g., 10-20 sheets) often reduces the per-unit cost. Some suppliers or online platforms may offer discounts for large orders.

- Shipping and Delivery Costs:

- For international shipping, such as from platforms like Alibaba or Made-in-China, the cost of delivery can significantly affect the overall price, especially for larger orders. Domestic suppliers like Home Depot or Lowe’s may offer lower shipping costs.

Tips for Saving Money of retailers:

- Buy in Bulk: Larger quantities often mean a lower cost per unit.

- Check for Sales or Discounts: Certain seasons or times of year (like Black Friday or holiday sales) may bring discounts on building materials.

- Consider the Long-Term Benefits: While premium sheets may cost more initially, they often save money in the long run due to their durability and low maintenance.

How to choose the best PVC UV panel ?

When choosing the best PVC marble sheet, several factors such as quality, design, durability, ease of installation, and cost should be considered. Here’s a breakdown of what to look for in a high-quality PVC marble sheet, along with some of the top brands that offer excellent products in this category:

Key Features to Look for in the Best PVC Marble Sheets:

- UV Resistance:

- High-quality PVC marble sheets should come with a UV-resistant coating to prevent fading and discoloration when exposed to sunlight. This is especially important if the sheets will be used in areas with a lot of natural light (like a living room, bedroom, or bathroom).

- Durability and Strength:

- A good PVC marble sheet should be durable, resistant to scratches, chips, and cracks, and able to handle impact without breaking. Look for sheets with high tensile strength and impact resistance, making them ideal for high-traffic areas.

- Surface Finish:

- The best PVC marble sheets should have a smooth, glossy surface that mimics the appearance of real marble. A high-quality finish will enhance the aesthetic and make it easy to clean.

- Some options also offer a matte finish, which is less prone to showing fingerprints or smudges.

- Thickness and Flexibility:

- Thicker sheets (typically around 3-5mm) are more durable and feel more like real stone, while thinner sheets (around 1-2mm) are lighter and easier to handle.

- Flexibility is also important for ease of installation in both flat and curved areas.

- Design and Color Options:

- The best PVC marble sheets should offer a variety of colors and patterns, including classic white marble, black marble, and even exotic colors and veining styles.

- Choose a sheet with realistic veining that closely mimics natural marble for a more authentic appearance.

- Water and Moisture Resistance:

- PVC is inherently water-resistant, but for the best performance in bathrooms, kitchens, and other moisture-prone areas, make sure the PVC sheets are specifically designed to be moisture-resistant and mildew-proof.

- Ease of Installation:

- Look for PVC marble sheets that are easy to install, either through adhesive bonding or interlocking panels. Some may come with peel-and-stick backing for DIY installations, while others may require traditional glue.

- Eco-Friendliness:

- Choose brands that focus on sustainable practices and eco-friendly production methods. Some PVC options are designed to be recyclable or made from recycled materials.

Best Use Cases for PVC Marble Sheets:

- Feature Walls: In living rooms, bedrooms, or entryways, PVC marble sheets can be used to create stunning feature walls. The black, white, or gray marble patterns work well in minimalist or modern styles.

- Shower Walls and Backsplashes: Since PVC marble sheets are waterproof and moisture-resistant, they are perfect for wet areas such as showers, bathrooms, and kitchens.

- Countertops: Use PVC marble sheets on kitchen counters or bathroom vanities for a stylish, cost-effective marble look.

- Furniture Surfaces: Apply PVC marble sheets to the surface of nightstands, coffee tables, and shelving units for a sleek, luxurious appearance.

Where to Buy the Best PVC Marble Sheets?

- Alibaba: Great for bulk orders from trusted manufacturers. Many suppliers offer high-quality PVC marble sheets with custom sizes, designs, and finishes.

- Amazon: Offers a range of PVC marble sheet options from various brands. Look for trusted sellers with good customer reviews.

- Home Improvement Stores: Local stores like Home Depot or Lowe’s may have a limited selection of PVC panels, including marble designs.

- Specialized Websites: Many suppliers like HiNiDeco (located in Haining,Zhejiang,China) sell directly through their own websites, offering more detailed information on their product lines.

What kind of glue used for PVC uv marble wall panel?

PVC marble sheet glue is an adhesive used specifically for bonding PVC marble sheets to surfaces such as walls, countertops, or furniture. Since PVC marble sheets are made of a plastic material, it’s important to choose the right type of glue to ensure a strong, long-lasting bond.

Types of Glue for PVC Marble Sheets:

- Contact Adhesive (Contact Cement):

- Best for: Large sheets or panels where you need a strong bond that resists peeling.

- Advantages:

- Provides an instant bond once surfaces come into contact, making it perfect for large, flat installations.

- Forms a flexible, durable bond.

- Works well for non-porous surfaces like PVC.

- How to Use: Apply a thin layer of adhesive to both the surface and the back of the PVC sheet. Allow it to dry until it’s tacky (about 5–10 minutes), then press the sheet firmly into place.

- Construction Adhesive:

- Best for: General installations on walls, floors, or countertops.

- Advantages:

- Designed for heavy-duty applications.

- Strong, flexible bond that holds even in high-stress environments.

- Resistant to water, making it suitable for use in bathrooms and kitchens.

- How to Use: Apply the adhesive evenly on the back of the PVC marble sheet or the surface to which it will be attached. Press the sheet firmly and use a roller to ensure an even bond.

- Epoxy Resin Adhesive:

- Best for: Situations where you need a permanent, high-strength bond.

- Advantages:

- Extremely strong and resistant to water, heat, and chemicals.

- Ideal for applications where the sheet will be exposed to heavy use or high temperatures.

- How to Use: Mix the two components (resin and hardener), then apply to the back of the PVC marble sheet. Once applied, hold the sheet in place until the adhesive sets.

- Polyurethane Adhesive:

- Best for: Strong bonding for vertical surfaces like walls.

- Advantages:

- Provides an excellent bond, even on rough surfaces.

- Water-resistant and durable.

- How to Use: Apply the adhesive to the back of the PVC marble sheet, then press the sheet firmly onto the surface. Use clamps or weights to keep the sheet in place while the adhesive cures.

- Glue for Peel-and-Stick PVC Marble Sheets:

- Best for: Easy DIY applications, especially in small projects or home renovations.

- Advantages:

- Ideal for peel-and-stick PVC marble sheets that already come with an adhesive backing.

- Simplifies installation by removing the need for additional glue.

- How to Use: Peel the backing off the adhesive and press the sheet directly onto the surface.

- Silicone Adhesive:

- Best for: High-moisture areas, like bathrooms and kitchens.

- Advantages:

- Highly flexible and water-resistant, making it perfect for damp environments.

- Forms a strong bond and is easy to clean.

- How to Use: Apply silicone to the surface of the wall or countertop and press the PVC sheet into place. Smooth the edges for a neat finish.

Considerations When Choosing Glue:

- Surface Compatibility:

- Choose a glue that is compatible with both the PVC marble sheet and the surface you’re adhering it to (wood, drywall, tile, etc.).

- Drying Time:

- Some adhesives, like contact cement, bond quickly, while others, like epoxy, may take longer to cure. Choose based on your project timeline and ease of handling.

- Moisture Resistance:

- If the PVC marble sheet will be installed in high-moisture areas (like bathrooms or kitchens), ensure the adhesive is waterproof and resistant to humidity.

- Weight of the Sheet:

- Thicker PVC sheets may require stronger adhesives like construction adhesive or epoxy for added bonding strength.

- Ease of Use:

- For DIYers, contact adhesives or peel-and-stick sheets are easy to work with and don’t require complicated steps.

- Application Area:

- If you’re using PVC marble sheets on walls, ensure the glue is suitable for vertical surfaces without dripping or running.

Step-by-Step Application for Installing PVC Marble Sheets:

- Prepare the Surface:

- Clean the surface thoroughly to ensure there is no dust, grease, or dirt. A clean surface helps the adhesive bond better.

- Cut the PVC Marble Sheets (if necessary):

- Use a utility knife or a saw to cut the sheets to the desired size before applying the adhesive. Measure the area carefully to avoid mistakes.

- Apply the Glue:

- Apply the glue or adhesive to the back of the PVC marble sheet (or directly on the surface, depending on the adhesive type). Follow the manufacturer’s instructions for the correct application method and coverage.

- Press and Align:

- Carefully press the PVC sheet into place, making sure it is aligned correctly. Once in position, apply even pressure to remove air bubbles or gaps.

- Let it Cure:

- Allow the adhesive to cure according to the manufacturer’s instructions. This usually takes anywhere from 24 to 48 hours, depending on the type of glue used.

- Finish Edges (if necessary):

- If needed, use a caulk or sealant around the edges of the sheet to ensure a clean, professional finish and prevent moisture from getting behind the panels.

Popular Adhesives for PVC Marble Sheets:

- Loctite PL Premium Construction Adhesive (Polyurethane-based)

- Gorilla Contact Adhesive

- Liquid Nails Heavy Duty Construction Adhesive (HiNiDeco suggest use this for PVC MARBLE UV WALL PANEL)

- 3M Scotch-Weld Epoxy Adhesive

- DAP Dynaflex 230 Premium Silicone Caulk

Golden/Glossy/Green/Black/Gray/White PVC Marble Sheet Which best selling?

The best-selling PVC marble sheets can vary depending on the market, design trends, and specific customer preferences. However, based on general industry trends and popularity in both residential and commercial settings, here’s a breakdown of how different colors and finishes fare in terms of popularity:

1. White PVC Marble Sheet (Best Seller)

- Why It’s Popular:

- Timeless and Versatile: White marble with gray or gold veins is the most classic and widely used design. It can fit into almost any décor style, from modern to traditional.

- Brightens Spaces: It creates a clean, fresh, and spacious feel, making it ideal for kitchens, bathrooms, and living rooms.

- Easy to Match: White marble pairs well with most furniture and wall colors, making it a top choice for versatile design.

- Applications:

- Bathrooms (Shower walls, vanity backsplashes)

- Kitchens (Countertops, backsplashes)

- Living Rooms (Feature walls, TV panels)

2. Black PVC Marble Sheet (Highly Popular)

- Why It’s Popular:

- Sophisticated and Modern: Black marble with contrasting white or gold veins gives an elegant and luxurious feel to any room.

- Dramatic Effect: Perfect for creating a bold and high-end look, especially in statement areas like feature walls or accent pieces.

- Increased Demand in Modern & Contemporary Designs: Black marble fits well with minimalist and industrial interiors, especially with gold or silver accents.

- Applications:

- Living Rooms (Feature walls, statement pieces)

- Dining Areas (Tabletops, decorative panels)

- Bathrooms (Shower panels, backsplashes)

3. Gray PVC Marble Sheet (Popular)

- Why It’s Popular:

- Subtle Elegance: Gray marble sheets are sophisticated yet not overpowering, making them a popular choice for contemporary and minimalist spaces.

- Neutral Tone: The neutral tone of gray allows it to blend with a wide range of colors and styles.

- Stylish Alternative to White: Ideal for those who want something softer or more modern than white.

- Applications:

- Living Rooms (Accent walls, furniture surfaces)

- Offices (Desk surfaces, walls)

- Kitchens & Bathrooms (Backsplashes, counters)

4. Golden PVC Marble Sheet (Moderately Popular)

- Why It’s Popular:

- Luxurious Look: Gold-veined marble gives a high-end, opulent look and is often used for more upscale or dramatic interior designs.

- Glamorous: Perfect for spaces where luxury and glamour are desired, such as hotels, lobbies, or high-end residential projects.

- Sophisticated Accents: Golden veins can create an elegant contrast, often used in combination with dark or light backgrounds.

- Applications:

- Luxury Interior Spaces (Feature walls, luxury bathrooms)

- Commercial Spaces (Lobbies, boutique shops)

- Furniture (Tabletops, paneling)

5. Glossy PVC Marble Sheet (Popular for Modern Looks)

- Why It’s Popular:

- Shiny and Reflective: The glossy finish enhances the marble’s veins and adds a modern touch. It is highly favored in contemporary designs, making rooms appear brighter and more spacious.

- Maintenance-Friendly: Glossy finishes are easy to clean and maintain, making them ideal for high-traffic areas or spaces that require frequent cleaning.

- Stylish and Sleek: Perfect for creating clean, polished aesthetics.

- Applications:

- Kitchens & Bathrooms (Backsplashes, countertops, shower panels)

- Feature Walls (Living rooms, reception areas)

- Commercial Spaces (Shops, galleries, or offices)

6. Green PVC Marble Sheet (Niche Market)

- Why It’s Popular:

- Unique and Trendy: Green marble with light or dark veins is a more unique and sometimes bold choice, making it ideal for customers looking for something different.

- Natural & Earthy Feel: Often used in spaces designed to bring a sense of nature and calmness, perfect for nature-inspired designs or eco-friendly interiors.

- Rising in Popularity: While it may not be as universally popular as white, black, or gray, green marble sheets are gaining traction due to the growing demand for more diverse and earthy tones.

- Applications:

- Eco-Friendly Interiors (Sustainable homes, nature-inspired spaces)

- Bathrooms (Shower walls, bathroom accents)

- Feature Walls (Living rooms, statement rooms)

Conclusion:

- Best-Selling Options:

- White PVC Marble Sheet stands out as the top seller due to its versatility, timeless appeal, and ease of integration into various designs.

- Black PVC Marble Sheet also sees high demand, particularly in modern, contemporary, and luxury spaces.

- Gray PVC Marble Sheet is a popular neutral option with broad appeal, especially in minimalist designs.

- Glossy Finishes (regardless of color) are generally more popular due to their sleek, high-shine effect that adds a polished, modern touch.

- Niche Choices:

- Golden and Green PVC marble sheets cater to specific tastes, with golden options targeting high-end, luxury projects and green appealing to eco-conscious or nature-inspired designs.

For businesses, focusing on white, black, and gray PVC marble sheets will likely yield the highest sales, with golden and green sheets serving niche markets.

Glossy vs. Matte which is better?

The choice between glossy and matte finishes for PVC marble sheets depends on various factors such as aesthetics, functionality, maintenance, and the specific application area. Both finishes have their advantages and drawbacks, and the “better” option largely depends on the look you’re going for and the intended use.

Here’s a detailed comparison to help you decide:

Glossy PVC Marble Sheets

Advantages:

- Sleek and Modern Look:

- The glossy finish offers a shiny, reflective surface that enhances the veining and patterns of the marble design, creating a more elegant and luxurious feel.

- It’s ideal for contemporary and upscale interiors.

- Brightens Spaces:

- Glossy surfaces reflect light, which can make spaces appear larger, brighter, and more open, especially in small or dark rooms.

- Easy to Clean:

- Glossy finishes are typically easier to clean since dirt, dust, and stains are more visible, prompting regular cleaning. Their smooth surface allows for quick wiping without much effort.

- Spills or stains are less likely to be absorbed, making it ideal for kitchen and bathroom areas.

- Aesthetic Appeal:

- Glossy PVC marble sheets are often used for high-end, luxury projects, such as feature walls, backsplashes, or premium countertops, because of their reflective surface.

Disadvantages:

- Visible Smudges and Fingerprints:

- Glossy finishes tend to show fingerprints, smudges, and water spots more clearly, especially in high-touch areas like kitchens or bathrooms.

- Higher Maintenance:

- While glossy sheets are easy to clean, they may require more frequent maintenance to maintain their shine and avoid the accumulation of dust and fingerprints.

- May Be Too Bold for Some Interiors:

- The high sheen of a glossy finish can sometimes feel too bold or overpowering in some design contexts, especially in more traditional or rustic settings.

Matte PVC Marble Sheets

Advantages:

- Subtle and Elegant:

- A matte finish has a softer, more understated look compared to glossy. It offers a more natural, timeless feel and can work well in a variety of design styles.

- Matte surfaces can often create a more relaxed, sophisticated atmosphere, suitable for minimalist or rustic interiors.

- No Smudges or Fingerprints:

- Matte finishes hide fingerprints, water spots, and dust much better than glossy finishes, making them a practical choice for high-touch areas.

- Since there’s no shine, smudges and marks are not as visible, resulting in less frequent cleaning.

- Ideal for Large Surfaces:

- Matte finishes tend to have a soft, even appearance without being too overpowering, which makes them great for large areas like feature walls, floors, or expansive countertops.

- It doesn’t create the same reflective glare, making it more suitable for darker rooms or areas that are already well-lit.

- Durability:

- Matte surfaces may be less prone to scratching, as the finish is often more resilient than glossy surfaces in terms of wear and tear.

Disadvantages:

- Less Brightness:

- Matte finishes don’t reflect light, which can make spaces feel darker or more enclosed, especially in smaller or poorly lit rooms.

- Dirt and Stains Can Be Harder to Spot:

- While matte finishes hide fingerprints, they can also hide dirt or stains that may build up over time, which can sometimes make cleaning less effective if not monitored regularly.

- Can Appear Less Luxurious:

- For some high-end projects or spaces looking for a polished, shiny effect, a matte finish may not provide the level of luxury and glamour that a glossy finish can offer.

Which Is Better?

1. Aesthetic Preference:

- Glossy: Best for those who want a shiny, modern, and luxurious look. It’s ideal for feature walls, modern kitchens, high-end countertops, and spaces that need a sleek and polished appearance.

- Matte: Best for those who prefer a softer, subtle, and more natural look. It suits minimalist, rustic, or traditional interiors and is great for larger surfaces or spaces where a more understated finish is preferred.

2. Functionality:

- Glossy: Ideal for small spaces that need extra light and brightness, such as bathrooms and kitchens. Also, great in high-traffic areas where cleaning is important, but you’ll need to stay on top of fingerprints and smudges.

- Matte: Better for larger surfaces like walls, floors, or offices, where you want a refined and understated aesthetic. Matte finishes are also more low-maintenance, particularly in high-touch areas.

3. Durability and Maintenance:

- Glossy: Requires more frequent cleaning to maintain its shine and avoid the buildup of marks. However, it’s easier to wipe down because of the smooth surface.

- Matte: Hides imperfections and stains better, making it easier to maintain in terms of cleanliness, but dirt may accumulate unnoticed.

4. Style and Trends:

- Glossy is favored in contemporary, luxury, and high-contrast designs.

- Matte tends to be more timeless, fitting into minimalist, Scandinavian, or industrial design styles.

Conclusion:

- If you’re aiming for a modern, sleek, and luxurious vibe, or need a bright, reflective surface to enhance a space, glossy PVC marble sheets are the better option.

- If you prefer a more subtle, sophisticated look or need something that requires less maintenance (with fewer fingerprints or smudges), then matte PVC marble sheets will be a great choice.

Ultimately, the better finish depends on the specific application and your personal style preferences. Many designers even combine matte and glossy finishes in different areas of a space to create contrast and add depth to the design.

How to install PVC marble wall sheet?

Installing PVC marble sheets is a straightforward process if you follow the proper steps and use the correct tools. Here’s a comprehensive guide on how to install PVC marble sheets for wall cladding, countertops, or decorative panels:

Materials and Tools Needed:

- PVC marble sheets (pre-measured or cut to size)

- Construction adhesive or contact adhesive (depending on your preference)

- Utility knife (for cutting sheets if necessary)

- Tape measure and level (for accuracy)

- Caulk gun (if using adhesive in tubes)

- Notched trowel (if using thick adhesive)

- Clamps or weights (to hold sheets in place while drying)

- Silicone sealant (for finishing edges, optional)

- Cleaning supplies (clean cloth, soap, and water)

Step-by-Step Guide for Installing PVC Marble Sheets:

1. Prepare the Surface:

- Clean the Wall or Surface: Ensure the surface where you plan to install the PVC marble sheets is clean, smooth, and dry. Use a cleaning solution to remove dust, dirt, grease, or any other contaminants.

- Smooth the Surface: If the surface is rough or uneven, consider sanding it lightly or using a primer for better adhesion.

- Measure and Mark: Use a tape measure to measure the area where you’ll be installing the sheets. Mark the area lightly with a pencil to ensure proper alignment.

2. Cut the PVC Marble Sheets (if needed):

- If the sheets are too large, use a utility knife or saw to cut them to the appropriate size. Score the surface with a utility knife, then snap the sheet along the scored line, or use a fine-toothed saw for precision cuts.

- Pre-cut and dry-fit the sheets to check for size and ensure they fit perfectly before applying the adhesive.

3. Apply Adhesive:

- For Contact Adhesive:

- Apply a thin, even layer of contact adhesive to both the back of the PVC sheet and the wall (or surface). Be sure to follow the manufacturer’s instructions for drying times.

- Let the adhesive become tacky (this usually takes about 5–10 minutes).

- For Construction Adhesive:

- Apply a thick bead of construction adhesive to the wall or surface using a caulk gun or a notched trowel for larger surface areas.

- If you’re using liquid nails or another construction adhesive, apply it in a zig-zag pattern to ensure good coverage.

- Optional: If you’re applying adhesive to the back of the sheet, make sure to spread it evenly using a notched trowel for a stronger bond.

4. Position and Press the Sheets:

- Place the PVC Sheet: Once the adhesive is tacky or ready, carefully position the PVC sheet against the wall or surface. Make sure to align it with your marks or measurements for a perfect fit.

- Press Firmly: Once the sheet is in place, press it firmly against the surface to ensure the adhesive bonds well. For larger sheets, you can use clamps to hold the sheet in place or apply weight on top while the adhesive cures.

- Check Alignment: Use a level to ensure the sheet is perfectly straight and aligned before the adhesive sets completely.

5. Repeat for Other Sheets:

- If you are covering a large area, continue applying adhesive and attaching the sheets one by one. Make sure to leave small gaps (about 1–2 mm) between the sheets for expansion and to allow for movement.

6. Secure and Finish Edges:

- Finishing the Edges: Use silicone sealant or a decorative trim to cover the edges of the PVC sheets, especially if the panels end against walls or corners. This will give a neat, clean finish and also help with sealing.

- Trim Excess: If there’s excess material along the edges, use a utility knife to trim it carefully.

7. Allow to Set:

- After all the sheets are installed, allow the adhesive to set and cure as per the manufacturer’s instructions. This typically takes about 24 hours for full curing, although some adhesives may dry faster.

8. Clean the Surface:

- Once the sheets are in place and the adhesive has dried, clean any adhesive residue off the sheets using a damp cloth. Ensure the surface is smooth and free from smudges.

- Polish the Surface: You can use a glass cleaner or a mild soap solution to clean the PVC marble sheets and restore their shine.

Tips for a Smooth Installation:

- Work in small sections if you’re new to the process. Applying too much adhesive at once can cause it to dry before you’re ready to install the panels.

- Pre-cut the panels to the correct size before you start applying adhesive to avoid cutting the sheets after they are installed.

- If you’re installing PVC marble sheets in a bathroom or kitchen, ensure the surface is moisture-resistant and that the adhesive you use is suitable for high-humidity areas.

- Seal the joints and edges with silicone sealant to prevent water from getting behind the panels, especially in high-moisture areas like bathrooms or kitchens.

- For large installations or areas with high traffic, consider using a more durable adhesive like construction adhesive for a stronger bond.

PVC Panel CHINA Export HS code?

For PVC panels exported from China, the HS code typically falls under the general classifications for plastic products used in construction or decoration. Here’s a more specific breakdown of the HS code for PVC panels that are commonly used in exports from China:

1. PVC Wall and Ceiling Panels (Decorative and Construction Use):

- HS Code: 3916.90

- Description: “Other articles of plastics and articles of other materials of heading 3901 to 3914, not elsewhere specified.”

- This HS code covers various PVC panels that are used for wall cladding, ceilings, and decorative purposes. It is one of the most common codes used for PVC interior panels exported from China.

2. PVC Sheets and Films (Used as Panels):

- HS Code: 3920.62

- Description: “Sheets, film, foil, and strip, of non-cellular plastics, not reinforced, laminated, or supported, of polyvinyl chloride (PVC).”

- This code is applicable to PVC sheets that can be used for cladding or paneling purposes. If your PVC panels are plain sheets used for construction or interior purposes, this code would apply.

3. PVC Building Materials (General Construction Use):

- HS Code: 3925.90

- Description: “Other builders’ ware of plastics.”

- This classification can apply to a range of plastic building materials, including PVC panels used for construction or wall systems in both residential and commercial applications.

4. PVC Panels (Exterior Use, Siding, etc.):

- HS Code: 3921.90

- Description: “Other plates, sheets, and film, of plastics, combined with other materials (like wood).”

- This HS code applies to composite PVC panels that might include other materials such as wood or fibers. It can also be used for PVC siding panels or exterior cladding.

Summary of Common Export HS Codes for PVC Panels from China:

- 3916.90: For PVC wall and ceiling panels (mostly used for decoration or interior applications).

- 3920.62: For PVC sheets or films that can be used as panels in construction or decoration.

- 3925.90: For PVC panels used as builders’ ware in construction (typically for wall cladding, etc.).

- 3921.90: For PVC composite panels (e.g., WPC panels or exterior cladding).

Important Notes:

- It’s always a good idea to verify the correct HS code with your customs broker or shipping expert, as the precise classification can depend on the exact material composition (pure PVC vs. composite) and intended use (interior vs. exterior).

- For China exports, the HS code should match the product’s actual use and composition to avoid delays or complications at customs.

A PVC marble sheet production line is a manufacturing setup designed to produce PVC (Polyvinyl Chloride) marble sheets used for wall cladding, flooring, countertops, and other decorative purposes. These production lines typically involve several key processes, including extrusion, mixing, calendaring, cooling, and cutting. Below is an overview of the stages involved in the production of PVC marble sheets:

How to produce PVC marble panel and What machine used?

PVC Marble Sheet Production line

Key Stages in PVC Marble Sheet Production Line:

1. Raw Material Preparation

- Ingredients: The primary raw materials used in producing PVC marble sheets are PVC resin, calcium carbonate, plasticizers, stabilizers, color pigments, and other additives.

- PVC Resin: The base material that forms the structure of the sheet.

- Calcium Carbonate: Adds stiffness and a marble-like texture.

- Plasticizers: Improve the flexibility of the material.

- Stabilizers: Help maintain the material’s durability.

- Color Pigments and Marble Effect Additives: For coloring and creating the marble pattern.

2. Mixing & Compounding

- Mixing Process: In this step, all raw materials are carefully measured and mixed together in a mixer to form a homogeneous compound. The compound typically includes PVC resin, calcium carbonate (to give the marble effect), and various additives for strength, durability, and flexibility.

- Extruder Mixing: Some production lines have a twin-screw extruder to combine the materials under heat and pressure. The heat activates the PVC resin, allowing it to blend with other ingredients.

3. Extrusion Process

- Extrusion Machine: The mixed material is fed into an extruder. The extruder melts the mixture and forces it through a die to form a continuous sheet.

- Sheet Formation: The melted material flows through the die to produce a flat sheet. The thickness of the sheet is controlled by adjusting the die gap.

- Surface Treatment: During extrusion, the surface of the sheet can be treated with embossing rolls to create textures or patterns (like marble veins or a glossy finish).

- The extrusion temperature and pressure are carefully controlled to ensure the sheet has the right density, flexibility, and appearance.

4. Calendering (Optional for Thickness Control)

- Some production lines use a calendering process instead of extrusion, where the material is passed through a series of heated rollers (calenders) to form thin sheets. The calendering process allows for precise control over the thickness and surface texture of the PVC sheet.

5. Cooling and Solidifying

- Once the sheet has been extruded or calendared, it needs to be cooled to solidify and set. This is usually done through a cooling conveyor or a water cooling system where the sheet is cooled at a controlled rate to prevent warping and to solidify the material for further processing.

6. Printing / Embossing (For Marble Pattern and Texture)

- Printing: A marble pattern is often applied using printing technology, such as UV printing or heat transfer printing. These techniques allow high-quality, detailed marble designs to be printed onto the surface of the sheet.

- The pattern can either be a random marble effect or a high-definition design that mimics natural marble veins.

- Embossing: To enhance the texture, some production lines use embossing rollers or 3D embossing to add a tactile texture that mimics the feel of natural marble.

7. Cutting and Shaping

- After cooling and embossing (if applicable), the long sheet is cut into standard sheet sizes (such as 1220mm x 2440mm, or custom sizes depending on customer requirements) using a cutting machine.

- Some production lines use laser cutting or sawing methods to achieve precision cuts.

8. Quality Control

- During and after the production process, quality control checks are conducted to ensure that the sheet thickness, marble pattern, and overall quality meet the required standards.

- Thickness Measurement: The thickness of the sheets is checked for consistency.

- Pattern Consistency: The marble pattern should be uniform and match the desired design.

- Surface Finish: The finish (glossy or matte) should be consistent, with no defects or irregularities.

9. Packaging

- After quality control, the finished PVC marble sheets are packaged for shipment. Packaging typically includes:

- Protective Wrapping: To prevent scratches and damage during transport.

- Stacking: Sheets are stacked in a manner that prevents warping.

- Labeling: Each package is labeled with size specifications and other relevant details.

Key Equipment in a PVC Marble Sheet Production Line:

- Mixer: For mixing raw materials like PVC resin, calcium carbonate, plasticizers, and other additives.

- Extruder: For melting and forming the PVC sheet, often with a custom die for shaping.

- Calendering Machine (Optional): For precise thickness control through heated rollers.

- Embossing Machine: To create textures and patterns on the surface of the sheet.

- Cooling System: To solidify the extruded material quickly and evenly.

- Printing Machine (UV or Heat Transfer): For applying marble patterns and designs.

- Cutting Machine: To cut the sheet into desired sizes.

- Quality Control Equipment: For testing thickness, surface finish, and pattern consistency.

- Packaging Machine: For wrapping, stacking, and preparing sheets for shipment.

Advantages of PVC Marble Sheet Production Line:

- Efficient and Scalable: Modern production lines are highly automated, making it easy to scale up production and maintain consistent quality.

- Customization: It allows for the production of PVC marble sheets in different sizes, colors, and finishes (glossy, matte, textured, etc.), depending on customer requirements.

- Cost-Effective: PVC marble sheets are typically more affordable than natural marble or granite, making them a popular choice for a variety of construction and interior decoration projects.

- Eco-Friendly: Many PVC marble sheets are made from recyclable materials and have a lower environmental impact compared to other materials.

The PVC marble sheet production line is a sophisticated process involving the careful preparation of raw materials, extrusion or calendaring, pattern printing, cooling, cutting, and quality control. By following the appropriate procedures and utilizing advanced machinery, manufacturers can produce high-quality, durable, and aesthetically pleasing PVC marble sheets for a wide range of applications in construction, interior design, and decoration.