What’s the current popular wall decoration material?

In 2024, the market is flooded with an abundance of wall decoration materials, including PVC panels, PU stone panels, fluted WPC panels, UV marble sheets, and wall paper, among many others. Each of these options offers unique benefits, but today, HiNiDeco is excited to introduce a product that’s currently making waves in the world of interior design—the 3D Self-Adhesive UV Marble Wall Sticker!

This innovative wall sticker combines the luxurious look of real marble with the convenience of a peel-and-stick application. It’s designed for those who want to achieve a modern, high-end aesthetic without the cost or hassle of traditional marble. With its 3D texture, it gives walls a realistic, elegant finish that transforms any room instantly.

Durable, waterproof, and easy to install, the 3D PVC marble wall sticker is perfect for kitchens, bathrooms, living rooms, or any space that needs a stylish upgrade. Stay ahead of the trend with HiNiDeco’s hot-selling wall sticker, offering beauty, practicality, and affordability all in one!

What is Adhesive UV Marble Sheet Wall Sticker?

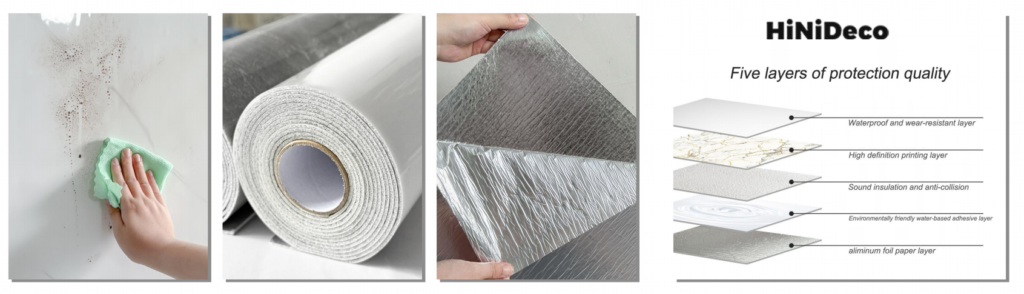

An Adhesive UV Marble Sheet Wall Sticker is a premium wall covering designed to replicate the look and feel of real marble. Made with advanced UV printing technology, it delivers a highly realistic marble appearance with vivid colors and intricate detailing. The adhesive backing allows for easy, mess-free installation—simply peel and stick onto various surfaces like walls, furniture, or countertops.

These sheets are durable, waterproof, and resistant to scratches, making them ideal for high-traffic areas such as kitchens, bathrooms, and commercial spaces. They are also UV-resistant, which means the colors won’t fade over time, maintaining their rich look even when exposed to sunlight. The material is lightweight and flexible, making it easy to apply on curved surfaces as well.

With its luxurious appearance, affordability, and low maintenance, an adhesive UV marble sheet offers a cost-effective way to achieve a high-end design. It’s perfect for DIY enthusiasts and professionals alike, offering a quick, stylish upgrade for any space.

Does UV marble sticker is popular by both consumer and seller?

The new marble wall sticker from HiNiDeco is incredibly user-friendly, making it perfect for DIY enthusiasts. With its simple peel-and-stick installation, 99% of walls can be easily transformed without the need for professional help, offering great value for money. For retailers, distributors, and wholesalers, this product is equally beneficial—it’s small, lightweight, and attractively priced, making it ideal for importing, shipping, and storage. Its compact size ensures hassle-free shipment and after-sales handling, providing a seamless experience from start to finish. Whether you’re a consumer or a business, this marble wall sticker is designed to meet your needs effortlessly.

This is the amazing new 2025 must-have wall sticker that you don’t want to miss! Right now, there are still great profit margins available for both retail and wholesale, making it a fantastic opportunity for business growth. Don’t wait—this chance won’t last forever! Contact HiNiDeco today at WhatsApp: +8619817052520 to seize this opportunity and stock the hottest wall sticker of the year!

Where is the manufacturer of uv marble sticker ?

The manufacturer of UV marble stickers is typically located in countries with strong production capabilities for wall decor materials, such as China, which is a major hub for producing a wide range of building and decoration materials. Many manufacturers/suppliers, including HiNiDeco, source and produce UV marble stickers in China due to the country’s advanced manufacturing technology, competitive pricing, and efficient logistics networks. You can contact manufacturers like HiNiDeco directly through their WhatsApp or email for more details or inquiries.

UV marble wall sticker VS UV marble sheet panel which is better ?

When comparing UV Marble Wall Stickers and UV Marble Sheet Panels, both have their unique advantages depending on the application and needs. Here’s a breakdown to help you decide which is better for your specific use:

UV Marble Wall Sticker:

- Lightweight and Flexible: Easier to handle and apply, especially for DIY projects. Great for renters or those looking for a quick and affordable wall upgrade.

- Easy Installation: Peel-and-stick application makes it hassle-free to install on most flat surfaces without professional help.

- Cost-Effective: Typically more affordable than sheet panels, offering a budget-friendly option for a marble look.

- Ideal for Small Projects: Perfect for smaller areas like backsplashes, accent walls, or furniture due to its ease of use.

- Temporary Solution: Since it’s easy to remove, it’s ideal for those who want a temporary or changeable design.

UV Marble Sheet Panel:

- More Durable: Thicker and sturdier than wall stickers, making it more resistant to wear, impact, and long-term damage.

- Professional Finish: Offers a more high-end, polished look that resembles real marble closely, ideal for large-scale or permanent projects.

- Suitable for High-Traffic Areas: More durable and better suited for commercial spaces, bathrooms, and kitchens where it can withstand heavy use.

- Longer-Lasting: As a permanent solution, UV marble sheet panels are more resilient over time and don’t require frequent replacement.

- Better Insulation: The thickness of sheet panels provides better insulation for sound and temperature compared to wall stickers.

Which is Better?

- If you’re looking for ease of use, affordability, and a temporary or small-scale solution, the UV marble wall sticker is the better choice.

- If you prefer a more durable, professional-grade, and long-lasting solution for larger spaces or high-traffic areas, the UV marble sheet panel is the superior option.

It ultimately depends on the project’s size, budget, and whether you want a temporary or permanent installation.

What’s the available size of the 3d pvc marble sticker? same as uv marble panel ?

The available size of 3D PVC marble stickers typically varies depending on the manufacturer, but they usually come in smaller, flexible sheets designed for easy application. Common sizes range from:

- 60 cm x 60 cm (24 inches x 24 inches)

- 60 cm x 90 cm (24 inches x 36 inches)

- 60 cm x 120 cm (24 inches x 48 inches)

These sizes make the 3D PVC marble stickers easier to handle, especially for DIY users, and they can be applied to smaller areas or tiled together for larger surfaces.

On the other hand, UV marble panels are generally larger and more robust, often used for bigger projects where a more professional finish is required. Typical sizes for UV marble panels include:

- 120 cm x 240 cm (48 inches x 96 inches) or

- 122 cm x 244 cm (48 inches x 96 inches)

Conclusion: The 3D PVC marble stickers are generally smaller, more flexible, and easier to manage, while UV marble panels are larger, more durable, and suited for bigger or more permanent installations. They don’t come in the same sizes due to their different purposes and material characteristics.

Does marble sticker has bigger size like 1.2x3m same as uv marble board ?

Yes, marble stickers can come in larger sizes, including dimensions like 1.2 x 3 meters. However, availability can vary by supplier. It’s a good idea to check with specific manufacturers or retailers to see if they offer that size. If you’re looking for something specific, HiNiDeco can help you find options.

Is there bigger size like 1.2x3m same as uv marble board ?

The best size for an adhesive marble wall sticker depends on the dimensions of the surface you’re covering and how you want to minimize seams or waste. Both 1.2 x 3m and 1.2 x 2.9m are large enough for many standard wall applications.

1.2 x 3m: This size is ideal if you want fewer seams when covering larger walls or want more flexibility in trimming to fit your space.

1.2 x 2.9m: Slightly smaller, but it could also work if your wall height matches this dimension more closely, reducing material waste.

If your walls are exactly or less than 3 meters in height, the 1.2 x 3m size would give you extra material to work with, allowing for better precision in installation. But if you have lower ceilings (e.g., 2.9 meters or below), you might prefer the smaller size. Contact us to make OEM or ODM service!

How to install the 3d foam marble wall sticker ?

Installing 3D foam marble wall stickers is a simple DIY process that can give your space a fresh and luxurious look. Here’s a step-by-step guide to help you through the installation:

Tools Needed:

- Measuring tape

- Scissors or utility knife

- Clean cloth or sponge

- A ruler or flat object (for smoothing)

Installation Steps:

- Prepare the Surface:

Ensure the wall or surface where you will apply the sticker is clean, dry, and smooth. Use a cloth or sponge to wipe off any dust, dirt, or moisture. For best results, avoid textured or uneven surfaces as they may affect adhesion. - Measure and Plan:

Measure the area where you want to apply the sticker to determine how many panels you will need. Plan the layout before applying the stickers, especially if you’re covering a large surface or creating a pattern. Cut the stickers to fit corners, edges, or any custom shapes with a scissors or utility knife. - Peel Off the Backing:

Carefully peel off the adhesive backing from the foam sticker. Start from one corner and peel gradually to avoid touching the adhesive part too much, as this may reduce its stickiness. - Apply the Sticker:

Line up the sticker with your planned layout and press it gently onto the wall. Start from one side and work your way across, smoothing it down with your hands as you go. You can use a flat object like a ruler or squeegee to press out any air bubbles and ensure it adheres evenly. - Trim Excess:

If needed, use a utility knife or scissors to trim any excess material along the edges, corners, or around obstacles like electrical outlets. - Smooth and Finish:

Go over the sticker with your hands or a flat object to ensure it is firmly attached and smooth out any remaining bubbles or wrinkles.

Additional Tips:

- Avoid installation on textured surfaces as it may not adhere properly.

- For extra adhesion, you can use spray adhesive or wallpaper glue if needed in areas with high humidity.

- Make sure the wall is completely dry before applying, especially if it has been recently cleaned.

Does it DIY-friendly ?

Yes, 3D foam marble wall stickers are very DIY-friendly! Here’s why:

- Easy Installation: They come with a peel-and-stick adhesive backing, so you don’t need any special tools or skills to apply them. Simply peel off the backing and press the sticker onto the surface.

- Lightweight and Flexible: The foam material is lightweight and flexible, making it easy to handle and adjust during installation. It can be cut with simple tools like scissors or a utility knife to fit your space.

- No Mess: Unlike traditional wall coverings, there’s no need for glue, nails, or grout, meaning no mess or hassle.

- Removable: If you make a mistake or want to change the design, many 3D foam wall stickers can be easily removed without damaging the wall or leaving sticky residue.

- Suitable for Most Surfaces: They can be applied to a variety of smooth surfaces, like walls, furniture, and even backsplashes, making it versatile for any DIY project.

Does it water-proof ?

Yes, 3D foam marble wall stickers are generally waterproof. This feature makes them suitable for use in areas like kitchens, bathrooms, and laundry rooms where moisture is present. Their water-resistant surface helps protect against splashes, spills, and humidity, ensuring they maintain their look and performance in damp environments.

However, it’s important to ensure proper installation, especially at the edges, to prevent water from seeping underneath the stickers, which could affect adhesion.

Does it anti-scratch well ?

Yes, many 3D foam marble wall stickers are designed to be anti-scratch or at least resistant to light scratches. The foam material has a protective outer layer that helps prevent minor scratches and scuffs, making them suitable for areas with light to moderate traffic. However, they may not be as resistant to heavy abrasion as harder materials like tiles or panels.

For high-traffic areas or surfaces prone to frequent contact, it’s good to be mindful of sharp objects or heavy use to maintain the sticker’s appearance over time.

HiNiDeco 3d marble adhesive sticker production line

How was the adhesive foam pvc marble sticker paper was produced ?

Producing adhesive foam PVC marble sticker paper involves several key steps. Here’s an overview of the typical production process:

1. Material Preparation

- PVC Resin: The primary material used is polyvinyl chloride (PVC) resin. This is often mixed with additives to enhance flexibility, durability, and appearance.

- Foam Formation: A foaming agent is added to the PVC mixture to create a foam structure, resulting in a lightweight and flexible material.

2. Sheet Extrusion

- The prepared PVC foam mixture is heated and extruded through a die to form a continuous sheet. This process allows for the creation of various thicknesses depending on the desired final product.

3. Surface Treatment

- Printing: The surface of the extruded foam PVC sheet is printed with a marble design using specialized printing techniques such as UV printing or digital printing. This step can include multiple colors and patterns to mimic the appearance of natural marble.

- Coating: A protective coating may be applied to enhance durability and resistance to scratches and moisture.

4. Adhesive Application

- A layer of adhesive is applied to one side of the printed PVC sheet. This adhesive is typically pressure-sensitive, allowing the sticker to be easily applied and removed without damaging surfaces.

5. Lamination

- The adhesive side may be laminated with a protective release liner. This liner keeps the adhesive surface protected until the product is ready for use.

6. Cutting and Packaging

- The laminated sheets are then cut into the desired sizes and shapes. After cutting, the stickers are packaged for distribution, ensuring they are ready for retail.

7. Quality Control

- Throughout the production process, quality control measures are implemented to ensure that the adhesive foam PVC marble sticker paper meets industry standards for adhesion, durability, and visual quality.

PVC Marble Sheet Self-Adhesive

Self-adhesive PVC marble sheets are a popular choice for quick and easy renovations. Here’s a breakdown of their features, advantages, and potential drawbacks.

Features

- Self-Adhesive Backing: Easy to install; simply peel off the backing and stick to the desired surface.

- Variety of Designs: Available in various marble patterns and colors, mimicking the look of natural marble.

- Water-Resistant: Suitable for areas exposed to moisture, such as kitchens and bathrooms.

Advantages

- Easy Installation

- No need for glue or additional adhesives; reduces installation time and effort.

- Cost-Effective

- Provides the look of marble at a fraction of the cost, making it budget-friendly.

- Lightweight

- Easy to handle and cut, allowing for seamless application on various surfaces.

- Low Maintenance

- Simple to clean with soap and water, requiring minimal upkeep.

- Versatile Applications

- Can be used on walls, countertops, furniture, and more, providing flexibility in design.

Disadvantages

- Durability Concerns

- While resistant to scratches, the self-adhesive layer may wear over time, especially in high-traffic areas.

- Heat Sensitivity

- Can be damaged by high temperatures; avoid placing hot items directly on the surface.

- Limited Lifespan

- May not last as long as traditional marble or other high-end materials.

- Surface Preparation Required

- The application surface must be clean, smooth, and dry for optimal adhesion.

- Less Authenticity

- While visually appealing, it may not have the same prestige or value as natural marble.

Self-adhesive PVC marble sheets offer a convenient and stylish solution for those looking to enhance their spaces without the hassle and expense of traditional marble. However, it’s essential to consider their limitations and suitability for your specific needs.